018 :: refining KiCad to Gcode workflow

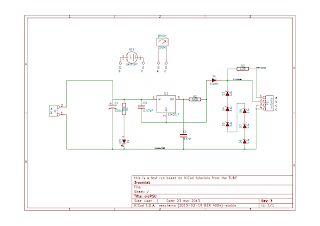

Yes, i am still using this weird looking circuit. Still grinding with it. Some slight mods this time, added a device into KiCad, a meter. Nothing to shout about, Kicad has a great GUI to work with, its a breeze.

Yes, i am still using this weird looking circuit. Still grinding with it. Some slight mods this time, added a device into KiCad, a meter. Nothing to shout about, Kicad has a great GUI to work with, its a breeze.This round i did some exploration on PCB track routing refinements, i believed many PCB hobbyists did what i did years ago, so much for being cooped up in the mountain for too long :p

Based on the new routing example, i have intentionally left out the "ground plane" or negative rail. In the next few process which leads to formation of a DXF and Gcode, I realised that due to the routing behavior of a PCB mill, i do not have to route any ground plane at all. It is like cheating, 1 less item to mill.

Screen grab this piece, without the whatever masks and markings etc etc.

Frame out the PCB at the cut edges in PS, and apply greyscale (remove color, you are only working on 1 single plane of copper anyway) + tweak the black and white scaling.

Frame out the PCB at the cut edges in PS, and apply greyscale (remove color, you are only working on 1 single plane of copper anyway) + tweak the black and white scaling.  Using this very nice piece of artwork, dump it into a PNG to DXF converter (quite commonly available). In the process of searching the universe for a proper vectorizing program, I have tried the following programs like a mini review :

Using this very nice piece of artwork, dump it into a PNG to DXF converter (quite commonly available). In the process of searching the universe for a proper vectorizing program, I have tried the following programs like a mini review :1) Magic tracer --> TONS of slider options, live preview. You need to sit there a day to get it. (i give this app a 5/10) 1 advantage of this bloke is, you can actually draw the vector in, so my take is this app is really powerful, and it could be used in some special works.

2) Raster 2 vector --> very easy to use, only 3 major parameters to play with. results is very good.(i give this app a 7/10)

3) potrace, MSDOS command line program. yes i know how to use a MSDOS cmd line. But no thanks

4) Vector Magic --> moderate amount of tweakables, ability to use internal engine which works REALLY well. (7/10 too !)

5) There are TONS of raster to vector apps out there, i am very sure there is one that will mind meld with you. But i found what i needed !

note that i have purposely left the outlines in the DXF trace so that there is a way to sync the scale of the process later on where possible.

Then after you have birthed the DXF, use the very nice DXF2GCODE converter ... and ... wala ! (see the pic of the sample gcode to the left, 6 pages of that to be exact in this particular case) However, at this point of time i have no idea if this does indeed translate to a true working and successful milling run, i have no hybrid cartesian machine to try it out yet.

Then after you have birthed the DXF, use the very nice DXF2GCODE converter ... and ... wala ! (see the pic of the sample gcode to the left, 6 pages of that to be exact in this particular case) However, at this point of time i have no idea if this does indeed translate to a true working and successful milling run, i have no hybrid cartesian machine to try it out yet.all thanks to the remarkable German bit of engineering from Mr Christian Kohlöffel (http://christian-kohloeffel.homepage.t-online.de/index.html)

So now the next step will be, calibrating the above process to a scale that fits an actual PCB. it could be at the PS process or it could be at the Gcode segment. due to the fact that my machine will be months away still, this will take some time.

(no step sticks are harmed in this experiment.) the above has been made possible after churning out 137 attempts at making any of the following : DXF, PNG, NGC etc etc etc.

26th March 2013 edit --> certain rasterizing programs have limitations. This puts a limitation on the size that can be converted directly 1:1 scale to about less than 3000pixels. contact has been made to ascertain other scaling possibilities so that this very nice methodology can actually be done for larger raster conversions ...

... to be continued

Comments

Post a Comment

feel free to ask me anything